Key Definitions

1. Visual management � This is a lean management technique designed to help employees to easily understand a work processes.

2. Just in Time Inventory Management (JIT) � A lean inventory management strategy that organizations use to boost efficiency of inventory management and to eradicate waste from the production process � thus minimizing the inventory costs.

3. 5S framework � This is the name of a workstation organization technique that uses a list of 5 Japanese words (seiri, selton, seiso, seiketsu, and shitsuke).

Introduction

According to Masaaki Imai, a Japanese expert in kaizen management practices and philosophies and an organizational theorist, "Kaizen is based on three pillars:

1. Housekeeping

2. Waste elimination

3. Standardization"

Pillar #1: Housekeeping

Housekeeping is the process of managing Gemba (workplace) to foster continuous improvement. M. Imani introduced the term Gemba, which means "actual or real place", where the value is added to a service or product before passing it to the next stage.

For proper housekeeping, the 5S framework is used.

The term "5 S" is derived from the first letters of various Japanese words known as five practices leading to a manageable and clean workstation: Shitsuke, seiketsu, seiso, siton, and seiri. The English terms equivalent of the Japanese 5S's are shown in the diagram below:

The 5S is a method of developing a culture that perpetuates a clean, neat, and efficient workplace; a means for removing excess tools and materials from the workstation and organizing the needed tools and materials so that they are easy to locate, to use, and to maintain. In short, 5S is all about locating what you need, exactly when you need it � no excess, no shortage.

The 5 Steps of the Japanese 5S Framework

The table below gives a brief guide on how to implement the 5-S framework.

|

Activity |

Description |

|

|

Meaning |

Process |

|

|

1.Seiri/Sort |

Remove anything - both materials and tools - that is not needed in the workplace for current process. |

1. Add a red tag to things that are not or maybe considered not needed in the current process. 2. Add a red tag to anything that that does not belong to the work station. 3. Give all employees a chance to show that any red tagged item is really needed. 4. Remove all red tagged things that no employee says are needed. 5. Ideally, sell them to employees, to scrap dealers, put to trash, or give them away. |

|

2. Selton or Set In order |

Setting up the workplace so that tools and materials are easy to find, use, and put back. |

1. Analyze and find the right place for everything. 2. Keep tools on pegboard, reassign cabinets, racks, spaces etc 3. Arrange items so that they are easy to use. 4. Label the items so that they are simple to locate and place back. |

|

3.Seiso/shine |

This step requires management to ensure that dirt, filth, dust, soot and stains are removed from Gemba. |

1. Divide the workstation into zones and allocate a specific person the responsibility of keeping it clean. 2. Determine the order of cleaning, type of the cleaning needed, etc. 3. Wash and paint to provide an attractive appearance. 4. Clean tools, oil and grease them, and inspect them for abnormalities. NB: Seiton is based on the principle that "there is a place for everything that's needed in the workplace." |

|

Seiketsu/ Standardize |

Visualize the 5-S steps in the workplace. In short, make the first 3 steps of the 5S framework an easy routine in the organization. |

1. Document guidelines and procedures for each of the first 3S of the 5S-framework. 2. Develop a quick checklist for the first 3S and train employees to follow them. 3. Conduct regular evaluation using the above check lists. |

|

Shitsuke/Sustain |

STANDARDIZATION and self-discipline |

1. Set up a cleaning schedule. Ideally, use downtime to straighten and clean areas |

Benefits of Using 5S in a Kaizen Organization:

-

Improves ergonomics and workplace safety.

-

Reduces searching.

-

Promotes flow.

-

Encourages visual control.

-

It enhances quality of products and services.

-

It enhances the commitment to standard work.

-

Eliminates distractions.

-

Enhances teamwork.

-

Reduces unplanned downtime.

-

It reduces inventory.

-

Tackles waste.

-

Improves productivity.

-

Reduces inventory.

-

It enhances self-management.

Pillar #2: Waste (Muda) Elimination

Lean management holds that resources in a process � machines and people � either add or don't add value to the product or services being processed. Any non-value adding resource is classified as Muda (a Japanese word meaning waste), and work is defined as a "series of value-adding tasks needed to convert raw materials into final products."

Kaizen seeks to improve business processes to eradicate the 7 types of waste as identified in lean management. The table below gives a description and examples of the 7 wastes as identified in lean management.

|

Waste |

Description |

|

1. Waste of transportation. |

Re-stacking, long moves, pick up/put down |

|

2. Waste of Waiting. |

� Time wasted waiting for anything. � Examples: equipment to be rectified, suppliers, management approvals, people, meetings without clear agenda, machine downtime, waiting for communication from customers, waiting for clarifications, etc. |

|

3. Waste of Over-processing. |

� Any step or process that does not add value from the client point of view. Processing beyond what is needed. � Example: A manager asks for the gross profit, but the accountant goes ahead to compute the net profit. |

|

4. Waste of Motion. |

� Unnecessary movement of workers. � Examples: Walking between offices to communicate with colleagues, walking to printers, shuffling through papers, walking back and forth between computer screens, disorganized computer files, etc. |

|

5. Waste of Defects. |

� Products, services and/or information that is late, inaccurate or incomplete. � For example, data entry errors, design flow, any error that is passed on to the next process, only for the product to be return for correction, absenteeism, employee turnover. � Defects cause customer dissatisfaction, and leads to waste or production time, and materials. |

|

6. Waste of Inventory. |

� Arises from ordering excess materials just in case they are needed. � Examples: Stock of anything: Emails, suppliers, paperwork, materials, archives, parts, any form of batch production, etc. � Kaizen goal � improve communication and relationship with suppliers to facilitate (Just in time inventory management (JIT). |

|

7. Waste of Overproduction. |

� Producing more than required � normally arise from production of goods based on estimated demand � push production. � Examples: producing extra copies, processing orders that might be changed, emailing people that don't really need to be cc'd. Printing documents that might need to be revised, etc. � Kaizen goal - improve and streamline processes so that a firm produces exactly what customers order exactly when they order it. |

The 5 Kaizen Waste Elimination Principles:

Kaizen focusses on identifying the root cause of the 7 type of waste and improving processes to eradicate it. Kaizen waste elimination is based on 5 principles:

1. Make the waste visible.

2. Be conscious (aware) of waste.

3. Have someone accountable for identifying waste in each workstation.

4. Measure the waste.

5. Improve the processes to eradicate waste.

The table below shows the most likely cause of each of the 7 types of wastes.

*NB: The list is not exclusive; it's good to conduct root cause analysis to see whether there are other causes of waste in your organization.

|

Waste |

Possible causes |

|

1. Waste of transportation. |

|

|

2. Waste of Waiting. |

|

|

3. Waste of Over-processing. |

|

|

4. Waste of Motion. |

|

|

5. Waste of Defects. |

|

|

6. Waste of Inventory. |

|

|

7. Waste of Overproduction. |

|

Pillar #3: Standardization

Standardizing work means developing standards at which production must be performed. A simpler way to think about standards is that production will be done to set specifications. Benefits of standardizing work include:

-

Waste elimination � standards are very effective in eliminating all the 7 types of waste.

-

Low costs.

-

Stable workflows.

-

Increased productivity.

Before implementing a standard, kaizen managers must ensure that it's appropriate for the organization, accepted by all involved in the process as attainable and fair, understood by everyone involved, and that the organization is committed to attaining it. Once a standard is adopted, kaizen requires the organization to continuously review its effectiveness and incrementally improve it.

A good standard must:

-

Represent the easiest, safest, and best way to do a job.

-

Provide the best way to preserve expertise and know-how.

-

Show the link between cause and effect.

-

Offer a basis for both improvement and maintenance.

-

Offer objectives and show training goals.

-

Create a basis for diagnosis or auditing.

-

Provide a basis for training.

-

Provide ways for minimizing variability and preventing re-occurrence of errors.

There are three main areas that need to be considered when developing standards:

-

Takt time � the duration given for a certain job to be completed

-

Work sequence � the step-by-step order in which all processing assembly work is to be done.

-

Standard in process stock � the optimal number of parts in process at any given time.

Hierarchy of Kaizen

Key Definitions

1. Overall Equipment Effectiveness (OEE) � A lean tool used to measure production performance.

2. Single-Minute Exchange of Die (SMED) � A lean production method of reducing waste.

3. Gemba � Real place such as the production floor.

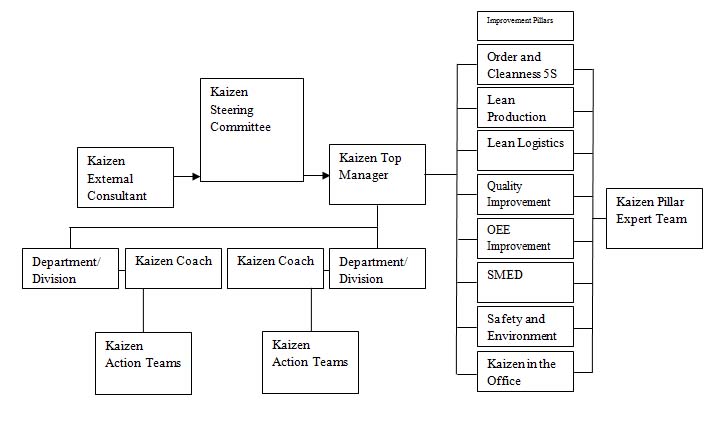

Introduction

A Kaizen organizational structure or hierarchy is the foundation on which kaizen is implemented in a firm. A kaizen hierarchy is a set of rules and policies that determine:

-

How a firm delegates tasks and controls responsibilities.

-

How decisions are passed and adopted throughout the firm.

-

How information flows within a firm.

Depending upon an organization's needs, there are different kaizen organizational hierarchies that can be used, but the kaizen functional structure is the most popular.

Functional Kaizen Organizational Structure

1. Kaizen Steering Committee

Management understanding, as well as commitment, is the first and the most important thing when implementing kaizen. Management must understand the nature of the whole process and then commit to it. First, a Kaizen Steering Committee must be chosen and put in place.

Kaizen Steering Committee includes:

� Top Management

� External consultants

� Kaizen manager

� Unions council

� Team leader (experts)

The Kaizen Steering Committee performs the following tasks:

� Determining the scope of activities.

� Setting the direction of the process.

� Ensuring that the necessary resources are available.

� Providing support and knowledge in difficult situations.

� Carrying our audit regularly and ensuring that corrections are done whenever necessary.

A Kaizen Steering Committee functions as follows:

� They hold regular meetings � intervals of four to six weeks.

� The meetings last for about 90 minutes.

� There is a defined structure for holding meetings.

� Results and decisions are visualized and communicated to the entire organization.

2. Kaizen External Consultants

External consultants have typically received wider consultation training than managers and have spent most of their time advising people � they are highly qualified and experienced (subject matter experts).

Employees may feel free to discuss problems with an external consultant than they would with a line manager, and these issues might be vital in the improvement process. This is because external consultants are not influenced by the firm's internal politics and thus, they are more likely to offer sensitive feedback and even maintain confidentiality and objectivity. Because of these benefits, subject matter experts are at times incorporated into the organization's kaizen coaching team. For example, a consultant specializing in sales techniques could be hired to support the sales team during a kaizen event.

The Kaizen External Consultants performs the following tasks:

� Advising and offering support throughout the process of change.

� Training and educating the employees involved.

� Assisting in difficult tasks and processes.

� Implementing a system of result control and visualization.

� Facilitating implementation immediately.

� Securing the Kaizen process via regular audits.

The Kaizen External Consultants functions in the following way:

� They conduct GEMBA workshops according to standards.

� They help in the creation of a roadmap of implementing Kaizen.

� They implement regular audits.

� They help to build-up a continuous improvement organization.

3. Kaizen Manager and Coordination Team

New, more "natural" types of organizations � self-organizing organizations, network organizations, self-managed teams, are allowing firms to be more adaptable and responsive in today's fast changing world. These organizations are also empowering employees more than the strictly structured firms of the past.

Just like the nature of organizations has drastically changed, so must the nature of managerial control. In fact, management should exist to help workers to be totally productive members of communities and organizations � they should not control the employees. Kaizen structure realizes this and it's the primary role of the Kaizen Manager and Coordination Team.

Therefore, the Kaizen Manager and Coordination Team perform the following tasks:

� Serving as the interconnecting link between the affected departments, the teams of experts, and the steering committee.

� Organizing the workshops � documents, invitations, etc.

� Verifying the implementation steps and actions.

� Reviewing the qualification of staff.

� Coordinating meetings, workshops, training, etc.

The Kaizen Manager and Coordination Team functions in the following way:

� They create as well as control standards for codes.

� They determine the qualification measures for employees.

� They design the roadmap and even coordinate the action plans.

� They organize training methods as well as techniques.

� They present and visualize the success.

4. Kaizen Coaches

Every kaizen organization needs a coach because the best way to learn a process is to study from a person who has been successful in one before. This individual has already tested and proven that the kaizen works. Employees must absorb all the information they require from this person � a kaizen coach is like a knowledge bank for the organization.

Many individual wants to change and be successful but they fail to invest in themselves and thus fail. They assume that they can teach themselves. "I can do this by myself." However, this is not the right path to follow. We all need coaches.

The Kaizen coaches perform the following tasks:

� They educate and train employees.

� They coordinate and implement Kaizen activities in their department.

� They help in the adoption of Kaizen actions.

� They help in maintenance of Kaizen board for their team.

The Kaizen Coaches functions in this way:

� They take part in the development of standard codes.

� They organize the adoption of standards.

� They document and monitor different actions.

� They plan for audit in their own department.

� They also visualize the success of their team or department.

5. Kaizen Pillar Expert Teams

The kaizen expert team is not just a group of professionals. It is a group of co-dependent team members with not only high level of task expertise but also mastery of the improvement process. A kaizen team member needs to have task-related job skills for job performance as well as teamwork skills to function efficiently as part of a co-dependent team.

Therefore, it is not just enough to create a team of task specialists or even technical experts but are not professionals in social interactions and relations � required for implementation of coordinative actions.

The Kaizen Pillar Experts Teams perform the following task:

� They create rules guiding the relevant knowledge pillars.

� They create organization-wide standards as well as guiding rules.

� They offer one ground support for teams with know-how and technical competence.

� They audit the processes regularly.

The Kaizen Pillar Experts Team functions as follows:

� They provide information on factory-wide rules and standards.

� They conduct the preparatory work for the Steering Committee when making the final decisions.

� They organize frequent team meetings of the experts.

6. Kaizen Action Team

Action planning helps the Kaizen Action Team to develop its goals, missions, and vision. Action planning helps to produce fast and visible results. The Kaizen Action Team strategizes, prioritizes, assigns tasks and even evaluates the progress. It takes easy, attainable steps that assist it to move forward.

The team is responsible for creating momentum through working on manageable-size kaizen projects.

The Kaizen Action Team performs the following tasks:

� They attend regular improvement meetings.

� They participate in further training.

� They participate in the process of solving problems in the team.

� They assume personal responsibility as well as sponsorship.

� They actively participate in the adoption of ideas.

The Kaizen Action Team functions as follows:

� They coordinate themselves across different shifts.

� They use similar methods and even inform their colleagues about changes.

� They hold meeting together and plan these meetings together.

7. Kaizen Department and Line Managers at GEMBA

A line manager, also called a direct manager, is an individual who directly manages business operations and other employees while reporting to a higher-rank manager.

The department and line managers play a vital role in the operation of an organization. They are responsible for managing resources and employees in pursuit of perfection and specific organizational or functional goals.

The Kaizen Department and Line Managers perform the following tasks:

� They support the process of continuous improvement.

� They participate in change workshops.

� They aid in implementation of actions.

� They also take part in the shaping of reasonable and feasible processes.

� They lead by example in improve met activities.

The Kaizen Department and Line Managers functions as follows:

� They create an environment for continuous improvement.

� They organize backfill or release for staff.

� They also organize the release of facilities and machine.

� They also support visual management.

� They also maintain the qualification matrix of employees.

Kaizen Involvement

The table below shows the hierarchy of Kaizen involvement.

|

Top Management |

Middle Management and Staff |

Supervisors |

Employees |

|

Determined to introduce Kaizen as an organization strategy. |

Deploy and adopt Kaizen objectives as directed by Top Management via policies deployment as well as cross-functional management. |

Implement Kaizen in functional roles. |

Participate in Kaizen via the suggestion system as well as small group activities. |

|

Offer support and direction for Kaizen by providing resources. |

Use Kaizen in functional capabilities. |

Design plans for Kaizen and offer guidance to employees. |

Practice discipline in the workshop. |

|

Enacts policies for Kaizen as well as other cross functional objectives. |

Design, upgrade, and maintain standards. |

Improve communication with employees and maintain high morale. Support individual suggestion system and small group activities such as quality circles. |

|

|

Attain Kaizen objectives via policies deployment and audit. |

Make workers Kaizen-conscious via intensive training programs. |

Maintain discipline in the workshop. |

Participate in continuous improvement process to become better problem solvers. |

|

Build procedures, structures, and systems conducive to Kaizen. |

Assist workers develop tools and skills for problem solving. |

Offer Kaizen suggestions. |

Improve skills as well as job-performance with cross-education. |