Handling Utensils and Food Supply in Kitchen Sanitation

Handling knives in the kitchen requires special care, both for health and safety reasons. Knives should always be kept sharp. Believe it or not, the sharper the blade, the lower the odds of cutting accidents. Think about it: If your blade is dull, you have to exert a lot more pressure on the item being cut. Not only will this crush your tomato or loaf of bread, it also increases the chances the blade will slip off of the intended cutting object and slice through your finger, instead.

Knife sharpening is best done by the chefs who will be using the knives, but either an electric sharpener or sharpening steel may be used to restore the knife edge.

Knives, like other kitchen equipment, need to be washed and sanitized between uses. Never move from cutting raw meat, fish, or poultry to cutting cooked foods or vegetables meant to be served raw without sanitizing the knife.

There are a bewildering variety of knives and knife handles. Before using a knife, make sure the handle has not become loose and wobbly. A knife with a loose blade is dangerous. Many knives have wooden handles. Wood-handled knives should not be allowed to soak submerged in water, nor should they be put in the dishwasher. The prolonged exposure to water may cause the wood fibers to swell and eventually splinter, meaning your knife will have a shorter life. You might also end up getting splinters in your hand.

It is possible to wash plastic-handled knives in a dishwasher, but there are some serious risks involved. The knife will be bounced around during the washing process, which may cause it to bump into glasses and plates. This could dull the blade. Also, the person who unloads the dishwasher may not be expecting a sharp blade in the rack, and they could accidentally slice their hand.

Once knives are clean and sanitized, store them in a knife rack or on a magnetic rack. Do not put them in a drawer or leave them sitting on a counter where they could cause injury or pick up cross-contamination from another source.

Only use kitchen knives for food. Do not open packages, or your mail, or clip your toenails, or cut your hair, with kitchen knives. Of course, this is ridiculous. No one would cut their hair with a kitchen knife. But many people do use paring knives to open boxes, which is completely unsafe and unsanitary, and it would dull the blade.

If you ever happen to drop a knife on the floor, do not try to catch it as it falls -- this is a good way to slice your hand. Just let it fall, making sure to move your feet out of the way. Of course, once it falls on the floor, it will have to be washed and sanitized again. There is no three-second rule in the commercial kitchen (nor should there be one in a residential kitchen).

As cutting boards age, they will get some cuts and nicks from knives. If the gouges become deep, the boards will be difficult to sanitize properly. At this point, the board needs to be replaced.

When cutting cooked meats, select cutting boards with a rim around the edge to help hold the juices before they leak all over counter tops and floor, not only creating a mess that you will have to clean up, but also increasing the potential for cross-contamination.

However, in a commercial kitchen, things are different. As mentioned previously, the stakes are so much higher, and so many more people (possibly people whose health is already shaky) are exposed to each worker's germs. Here is a basic list of guidelines for dish handling. Check your state and local requirements, and also be sure to understand your facility's specific procedures.

- Always wash hands before handling clean dishes.

- If wearing gloves, either wash them, or put on a clean pair.

- Do not stack wet dishes; they need to be exposed to air in order to dry properly.

- Do not let water pool up in the bottom of glasses, bowls or cups.

- Store glasses and cups upside-down so that they dry properly and dust does not accumulate inside.

- When handling dishes, be on the lookout for dried-on bits of food or lipstick stains.

- Do not let your fingers touch parts of the dishes that people will drink or eat out of.

- Hold cups by the outer surface, not by the rim.

- Do not put hands inside glasses.

- Do not dry off dishes with a towel -- let them air dry.

- Pick up silverware by the stems, not the parts that touch the food.

- Be particularly careful about coughing and sneezing while handling dishes.

- If you happen to accidentally cough or sneeze on the clean dishes, make sure they are re-washed.

- Keep your eye out for any signs of pest infestation around the clean dish storage area.

As the U.S. government has begun to take a closer look at all the possible ways terrorists could potentially threaten the United States, scientists and federal agencies have begun to take a closer look at the food supply in this country. Just as people in the past have used medicines, like Tylenol, and vehicles, like airplanes, as weapons, it is possible that an enemy of the state might eventually contaminate our food supply. We have also heard stories of imported food from other countries with different laws about the kinds of chemicals that may be used on foods. and the kinds of food-handling practices in place. In a country with less regulation about food production practices, it is difficult to know exactly how food was grown, harvested, or processed.

The food industry is continually working to improve safety and quality of product. One way facilities improve is through adopting a Hazard Analysis and Critical Control Points (HACCP) program (pronouncedhassip). The topic of HACCP could be an entire course in itself, but in the following lesson, we will provide a brief summary of what these programs involve, how they can be beneficial to your business, and what you can do to incorporate HAACP components into your kitchen, even if you are not using full HACCP program. HAACP is a voluntary process, but one that can greatly improve the safety and efficiency of your kitchen. It looks at the whole system of food preparation, instead of individual parts, and seeks to improve the overall process so that the end product, your food, is as safe as possible.

HACCP was developed decades ago as part of the space program. The purpose of the original program was to eliminate or reduce as many risks as possible for astronauts. If food poisoning is unpleasant on earth, imagine what it would be like when stuck in a space capsule orbiting the earth for three days.

One of the ways scientists limited risk was to analyze every step in each of their processes to identify any points where contamination might occur, and then work to minimize the risk at each of those steps. One of the most easily-applicable parts of HACCP is instituting standard operating procedures or SOPs, so that basic job functions are always performed in the same way. If you think about it, a recipe is in SOP itself -- it is a written guideline for preparing a particular food item in exactly the same way each time. This provides for consistent quality and product, which not only enhances safety and reduces risks, but also improves the customer experience.

Here's how you can apply HAACP to your food service applications:

- Analyze hazards: Look at the whole process of food preparation in your facility. Think about how foods are received, how meals are prepared, where they are held, and how they are served. Look at the menu. What items on the menu pose a high level of risk? For example, any step in the process that involves holding foods at cold or high temperatures involves some risk: What if the cooler stops working for a period of time and your egg salad gets too warm?

- Identify critical control points: Once you have analyzed the process and given thought to all the hazards, identify which steps are absolutely essential to keeping foods safe. Hot or cold storage points are usually critical points.

- Establish preventive measures with limits at each point: Once you know the steps in the process where problems are most likely to occur, look for ways to keep problems from happening. Using our temperature control example, make sure to check temperatures often in hot and cold holding areas. Understand what the limits are at these steps: for example, the temperature in the cooler should always be below 41�F. If it ever rises above this acceptable level, then employees should know how to respond.

- Establish procedures to monitor the critical control points:How often will you check the temperature in the cooler or on the buffet line? Who is responsible for checking it?

- Establish corrective actions: What do employees do when the critical control points are outside their established limits? For example, what if the daily temperature check inside the cooler shows that the cooler has reached 45�F?

- Establish procedures to verify that the system is working properly: It's not enough just to trust the thermometer; you have to be sure the thermometer is working accurately, too. Have a plan in place to verify the accuracy of your equipment. For example, you could periodically use two thermometers to check temperatures.

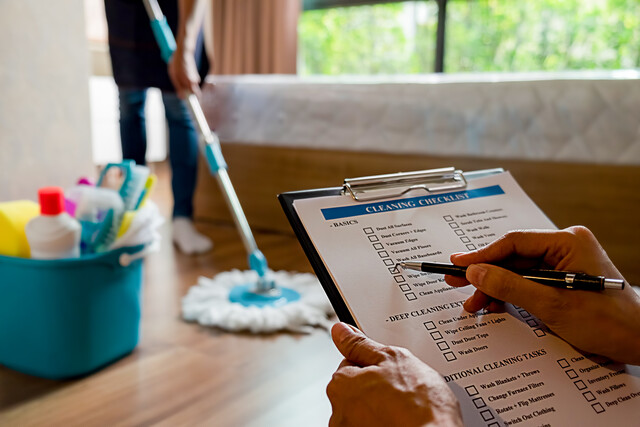

- Establish effective record keeping: Use checklists with signatures so that you know each step in the process has been performed.

The HACCP team should definitely include the executive chef, the sous chef, at least one server, and several other experienced members of the staff.

Some written tools you can use in training include:

Job descriptions: A job description is the view of your job from 10,000 feet. It does not go into extensive detail, but it lists the basic job functions. In general, a job description should be no more than one page long. Both supervisors and people doing the job should work on writing it, and it should include both standard tasks for that job and a catch-all phrase like "and other duties as assigned." Having a clearly defined job description helps people understand if they are doing everything they are supposed to be doing, and it also helps supervisors perform appraisals, because there is a clearly-defined set of expectations. For a server, a job description might include items like presenting a clean and well-groomed appearance, greeting customers, taking food orders, serving food promptly, and ensuring a positive customer experience.

The job description would not go into great detail about all the specific tasks involved in taking food orders. Detailed explanations are better suited to job breakdowns.

Checklists: Somewhere between the job description and the job breakdown is the checklist. This is just a simple list, without any kind of how-to detail, of all the jobs that have to be done at certain points in the shift. A bartender's closing checklist would include items like:

-

Last call at 1:30

- Turn on lights at 1:45

- Remove drunks at 1:55

- Lock doors at 2:00

- Close register

- Count money

- Add up credit card receipts

- Balance money against register report

- Record discrepancies

- Complete shift log

- Empty & sanitize sinks, bar, counters, seats and tables

- Label and put away leftover garnishes

- Sweep floor

- Complete bar order for the next day

- Lock liquor cabinets

- Turn in cash at the manager's office

- Turn off lights

- Lock up and leave

Workers can split up all the items on the checklist, and then as they are completed, they enter the time of completion and their initials. Having to put their initials next to each item adds an element of accountability, so everyone knows who did what, and when.

Improving documentation in a restaurant not only helps create a more responsible workplace, it also shows the health department that you are serious about doing things the healthy way.