A business philosophy for institutional buying and vendor relationship management, or supply chain management, is an essential functional role within any organization. Organizations, large and small, have some form of a purchasing function. Even a sole-proprietor is responsible for purchasing the necessary goods and services to keep their business running. So when we consider the importance of a well-defined, well-engineered supply chain management function, the implications, organizationally, are widespread and certainly worth noting.

For the sake of simplicity the following terms will be considered synonymous:

|

Purchasing & Vendor Management |

Supply Chain Management |

|

Purchaser |

Buyer |

|

End User |

Customer |

|

Vendor |

Supplier, Contractor |

|

Total Life Cycle Cost |

Total Cost of Ownership |

Consider the purchasing function within your own business, or a business you might be familiar with, such as a school parent association, homeowners association, or church. Decisions are made to purchase goods and services almost daily right? Well those daily decisions can and do have a bottom line impact on the organization's income statement. It is essential for the sake of having a system of checks and balances that an organization's supply chain management system be independent.

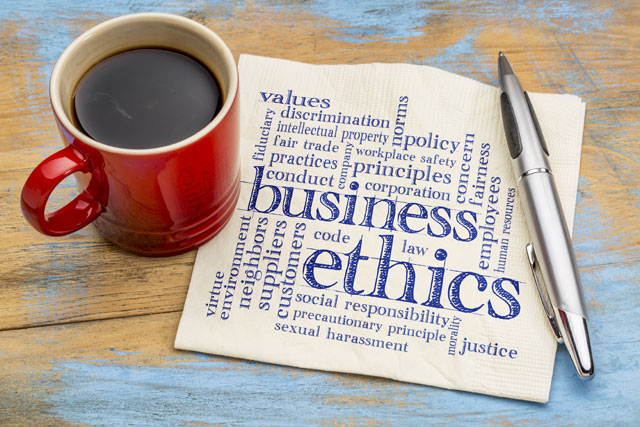

Independence creates a system of anonymity and prevents biased purchasing decisions that we typically find when the end user of the proposed purchased good or service is also making the purchasing decision. Why might that be? Think about this in your personal purchases; quite often we are prone to impulse purchasing decisions based on our own preference. That preference might be based on experience, marketing impact, or a number of other variables.

While there is a need for independence for the purchasing and vendor management function of an organization there might be situations where it simply is not possible to have this system of independence. In such cases, the purchaser must be vigilant, recognize their own personal biases, and be prepared to make the right decisions based on data, not personal preference. It is essential to remember the independence is meant to serve as a system of checks and balances that separate the end user requesting the purchase, from the vendor, supplier, or contractor delivering the product or service.

Case Study 1:

Jim is the maintenance manager for a manufacturing organization and recently requested the purchase of a new pump to replace an outdated pump in the factory. Jim has for a number of years become quite familiar with the local supplier of pumps and has even engaged in out-of-work social activities with the vendor.

The vendor has recently asked Jim to attend a professional sporting event. While at the event the vendor asks Jim when he will receive a purchase order for the replacement pump. Jim tells him not to worry about it, that he will get the purchase order to him next week after he has a chance to speak to the purchasing manager.

Case Study Debrief:

There are a number of things that should immediately be recognized as wrong by even the most inexperienced, or novice person within case study 1. First, it is generally considered to be inappropriate to accept gifts from vendors. By accepting the invitation to the sporting event Jim has put himself in a questionable position ethically and professionally if his organization has a policy forbidding the acceptance of gifts (which most do). 2. Jim has clearly let his personal relationship with the vendor influence his purchasing preferences. 3. Jim feels as though he can influence the purchasing manager's decision in favor of this particular vendor.

Through this case study we should be able to clearly recognize why the purchasing and vendor management function of an organization should, if possible, function independently. We will hopefully also recognize some easily identifiable inappropriate behaviors on Jim's part that, in most cases, would be prohibited in an institutional setting.

It is quite easy for many functions within an organization to tout their function's value. Let's explore some functional areas and how they create organizational value.

|

Sales |

Creates revenue |

|

Marketing |

Creates demand |

|

Quality |

Maintains or enhances brand equity |

|

Maintenance |

Delivers production uptime |

|

Production |

Produces product to be sold |

Often we look at functions within an organization, as we can easily see their contributions to the organization, such as in the examples above. Purchasing and vendor management, or supply chain management is an area where there is also an opportunity for tremendous value to be derived. Let's explore the value proposition of this function.

The first step in the purchasing process is to specify the purchase.This is typically done by the end user; however, this may also include input from a variety of organizational functions. When we specify a purchase, we are outlining in the greatest possible detail, the desired characteristics of the good or service we intend to purchase.This stage of the purchasing process is critical, as it establishes the very nature of what you expect the vendor, supplier, or contractor to deliver.

When specifying, some key considerations might be delivery, price, origin of materials, quality of materials, or other desired characteristics. The key is that specifying be as detailed as possible so you get exactly what you specified.

Case Study 2:

Jim must specify the pump characteristics from Case Study 1 for the buyer to source the purchase. Jim specifies the following:

Pump, Centrifugal - 8" inlet and outlet, cast body, stainless steel impeller, with mechanical seal, capable of 300 gallons per minute flow at a base pump efficiency of 90 pounds per square inch.

Case Study Debrief: Considering what we learned in Case Study 1, it is encouraging to see that Jim did not specify a vendor, or manufacturer of choice. The specification is detailed, yet generic enough where multiple vendors or manufacturers could fulfill this order.

Once the end user has specified the purchase, it would normally be added to a purchase requisition.This requisition is what the buyer will use to source the product or service.There are a number of key considerations that should be explored prior to approving a purchase.

1. How is the purchase prioritized within the buyer's work flow? Obviously there will always be some purchases that are more important than others, or that must be expedited.

2. Is the purchase budgeted? If it is not budgeted for, does the purchase requisition have a secondary approval?

3. Does the purchase fall within the requisitioner's area of responsibility and purchasing authority? If not, is there secondary approval?

4. Are their multiple sources that could fulfill the requisition? If not, then a sole source justification should be completed and approved.

5. Has the requisitioner adequately specified the product or service?

Upon considering the approval considerations it is the buyer's job to source the purchase. Sourcing a purchase can be a daunting task. There are a number of strategies for sourcing vendors; however, the best approaches typically place a very high emphasis on the Total Cost of Ownership, or Total Life Cycle Cost. Total Cost of Ownership, or Total Life Cycle Cost, is an attempt to estimate the entire cost of owning an asset/product. This approach is not relevant for service purchases.

Example from Case Studies 1 & 2:

|

Pump, Centrifugal |

Total Energy/Operating Cost for life: $13,384 |

|

Pump, Centrifugal |

Total Maintenance Cost for life: $4,356 |

|

Pump, Centrifugal |

Total Life Cycle Cost: $17,740 |

If a buyer is sourcing raw materials, or a service, we have already discussed that Total Cost of Ownership would not be applicable; however, the buyer can still evaluate a number of different elements to arrive at the best buying decision for the organization. Elements such as availability, quality, price, delivery, and elements of the terms and conditions are all critical elements to a raw material or service purchase.

Preferred vendors or suppliers are a very important function within the supply chain management function.This area is a critical opportunity for the supply chain management function to interface with the other functional areas within an organization -- particularly since the other functions typically have a much better understanding of their needs and the best product or service and associated vendor that can best deliver based upon their needs.

Going back to the initial case study, there may be a very good reason why Jim would choose the vendor he has an established social relationship with. It might even be 100 percent valid and worthy of awarding the purchase order to Jim's vendor friend, but only after conducting significant due diligence on the part of the supply chain management team should that be done.

Preferred vendor or supplier status should denote a level of confidence and trust in the vendor's product or service, the delivery, and the quality thereof. Therefore a cross-functional team should be created whenever there is consideration being made to create a preferred vendor or supplier relationship. The following table contains some important questions that should be answered when evaluating vendors for preferred status.

|

Does the supplier's culture closely align with the organization's? |

Does the vendor's credit rating (if applicable) indicate a high level of credit worthiness? |

|

Does the supplier meet or exceed quality specifications? ISO,etc. |

Do the vendor's credit references indicate a high level of credit worthiness? |

|

Do the supplier's terms and conditions align with the organization's? |

Does the vendor have a BBB rating? If so, are there any complaints? Unresolved? |

|

Does the supplier maintain adequate inventory to meet the needs of the organization? |

Is the vendor's pricing competitive? |

While this list of questions should serve as a guide, you might find that your organization's needs require further elaboration, or research. Most importantly, it is essential that we do not enter into preferred relationships without first having completed some level of due diligence.

Contracts, and the management thereof, are another essential function of the supply chain management function. In order to achieve the desired results, contracts, when initially created, should again utilize cross-functional teams. All parties of a contract must be prepared to deliver, and be held accountable for, the terms set forth within the contract. A final note regarding contracts and preferred vendor relationships: Prior to entering into any of these, one should seriously consider having the legal team offer input and final review.

The last step in the purchasing process is the issuance of a purchase order. Purchase orders are typically issued by the buyer, and only after all previous steps and considerations within the process have been completed.